| Cracks in Brickwork |

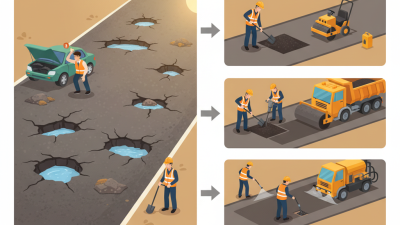

Vertical or horizontal cracks can develop due to settling or temperature changes. |

Prepare cracks by cleaning them, apply vinyl concrete patch or mortar. |

Putty knife, wire brush, patching compound. |

1-2 hours |

| Brick Spalling |

Surface of the brick begins to flake off, often due to moisture. |

Remove loose pieces and apply a waterproof sealant. |

Hammer, chisel, sealant. |

2 hours |

| Loose Mortar Joints |

Mortar can crack and crumble, compromising the structure. |

Remove damaged mortar and repoint it with new mortar. |

Trowel, mortar mix, jointing tool. |

3-4 hours |

| Water Damage |

Excess water can cause structural and aesthetic damage. |

Identify source of water, repair damage, and apply water-resistant coating. |

Pressure washer, patching materials, sealant. |

6+ hours |

| Efflorescence |

White powdery substance on brick surface, caused by salt. |

Scrub with a stiff brush and clean water; seal to prevent recurrence. |

Stiff brush, water, sealant. |

1 hour |

| Misaligned Bricks |

Bricks may shift due to foundation movement or poor installation. |

Reposition bricks, replace damaged ones, and secure with mortar. |

Chisel, mortar, rubber mallet. |

3-5 hours |

| Chimney Damage |

Cracks or missing bricks can lead to dangerous conditions. |

Inspect and repair with proper sealing and cement. |

Ladder, sealant, cement. |

4-6 hours |

| Paver Settling |

Pavers can sink or become uneven over time. |

Lift pavers, add base material, and reset pavers. |

Paver level, base material. |

2-3 hours |

| Cracked Mortar |

Old mortar can crack and crumble, causing instability. |

Remove cracks and apply fresh mortar; ensure proper beveling. |

Grout bag, trowel, new mortar. |

2-4 hours |

| Cracked Foundation |

Foundation cracks can lead to significant structural issues. |

Evaluate depth, apply epoxy filler, and monitor. |

Epoxy filler, trowel. |

3-5 hours |